Get a 3D Printing Quote

We have a fast and easy to use online ordering and quoting system open 24/7.

With functional prototyping, you can test different designs for your product until you achieve the desired effect. Some factors to consider include model density, flexibility required, tolerances and component fit. You can test all these factors using a 3D printed prototype.

Here is an example of the multiple iterations we developed to bring The Third Thumb project to life. Multiple design and model print settings were tested before arriving at the final version of the product.

The look of your product is another important point. You can test multiple aesthetic choices quickly using 3D printed prototypes, such as colour, material and design variations.

With 3D printing, you can manufacture your prototype in a range of materials. As well as PLA bioplastics, we also offer 3D prints in wood, brass, copper, steel and bronze composites.

For more flexible prototypes, we offer rubber-like TPU materials with various Shore Hardness such as NinjaFlex. We can also 3D print with high durability materials like Polymax (20% stronger than ABS), and high temperature resistant materials, among others.

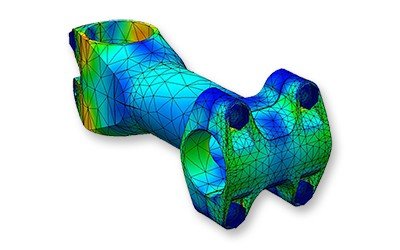

Test the quality of your product by destroying it! We can 3D print prototypes for strength, stress, and durability testing. And don’t forget to test those tolerances to ensure a good fit.

We have a fast and easy to use online ordering and quoting system open 24/7.